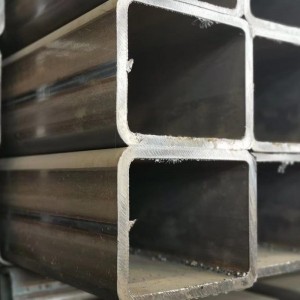

Tuubbada laba geesoodka ah ee hore-galvanized

1. 16mn Continental Square Tube

Halabuurka kiimikada: carbon C: 0.17 ~ 0.24 "silikon Si: 0.17 ~ 0.37 manganese Mn: 0.35 ~ 0.65 baaruud S: ≤ 0.035 fosfooraska P: ≤ 0.035 chromium Cr: ≤ 0.25 nickel Nickel

2. 16mn tube square

Halabuurka kiimikada: kaarboon C: 0.17 ~ 0.24 "silikon Si: 0.17 ~ 0.37 manganese Mn: 0.35 ~ 0.65 baaruud S: ≤ 0.035 fosfooraska P: ≤ 0.035 chromium Cr: ≤ 0.25 nickel Nickel: 0.25 nickel 0.25

1.1 Caag

Balaastiigu waa awooda shay macdan ah si uu u soo saaro qallafsanaanta balaastiigga ah (qalafsanaanta joogtada ah) ee culeyska hoostiisa iyadoon waxyeello gaarin.

1.2 Adag

Adaggu waa tilmaanta heerka engegnaanta ama jilicsanaanta walxaha macdanaha ah. Habka ugu badan ee loo isticmaalo in lagu go'aamiyo adkaanta wax-soo-saarku waa habka qallafsanaanta, kaas oo adeegsada gelinta joomatari gaar ah si uu ugu cadaadiyo dusha sare ee walxaha birta ah ee la tijaabiyay ee ku jira culeys gaar ah oo go'aaminaya qiimaha engegnaanta iyada oo loo eegayo heerka la riixayo. galay.

Hababka inta badan la isticmaalo waa Brinell hardness (HB), Rockwell hardness (HRA, HRB, HRC) iyo hababka Vickers hardness (HV).

1.3 Daal

Xoogga, balaastigga iyo qallafsanaanta hore looga hadlay ayaa dhammaantood tilmaamaya sifooyinka farsamada ee birta ee culeyska taagan. Dhab ahaantii, qaybo badan oo mishiin ah ayaa ka shaqeeya culeysyo wareeg ah, iyo xaaladahan oo kale qaybaha waxay soo saaraan daal.

1.4 Saamaynta adagaanta

Culayska ku shaqeeya qaybta mishiinka ee xawaaraha weyn waxaa loo yaqaan culeyska saameynta, iyo awoodda birta si ay uga hortagto dhaawaca hoos yimaada culeyska saameynta waxaa loo yaqaannaa adkaanta saameynta.

1.5 Xoog

Xooggu waa iska caabbinta walxaha birta ah inay waxyeeleeyaan (qallafsanaanta balaastiigga xad dhaafka ah ama jabka) hoos yimaada culeys taagan. Sida ficilka culeyska ee qaabka jilicsanaanta, isku-buufinta, foorarsiga, dhogorta, sidaas darteed xoogga sidoo kale wuxuu u qaybsan yahay xoogga xajinta, xoogga xoogga, xoogga qalooca, xoogga dhogorta, iwm .. Inta badan waxaa jira xiriir gaar ah oo u dhexeeya xoogga kala duwan, isticmaalka xoogga xajinta guud sida tilmaame xoogga aasaasiga ah.

Tuubbada labajibbaaran waxaa loo isticmaalaa dhismaha, wax-soo-saarka mishiinnada, mashaariicda dhismaha birta, dhismaha maraakiibta, tamarta tamarta qoraxda, injineernimada qaab dhismeedka birta, injineernimada tamarta, dhirta korontada, mashiinada beeraha iyo kiimikada, darbiyada daahyada, chassis baabuurta, garoomada diyaaradaha, dhismaha kuleyliyaha, biraha wadooyinka weyn. , Dhismaha guryaha, maraakiibta cadaadiska, haamaha kaydinta shidaalka, buundooyinka, qalabka korontada, mashiinada qaadista iyo gaadiidka iyo qaybaha kale ee rarka badan ee alxanka dhismaha, iwm.

Habka kala soocidda

Tuubbada labajibbaaran waxaa loo kala saaraa si waafaqsan habka wax-soo-saarka: tuubo labajibbaaran oo kulul oo duuban, tuubo labajibbaaran oo qabow la jiido, tuubo labajibbaaran oo aan fiicneyn, tuubo laba jibaaran oo alxan leh.

Waxaa ka mid ah, tuubo labajibbaaran oo welded ayaa loo qaybiyaa

1. sida ku cad habka - tube alxanka arc, tuubo laba jibbaaran alxanka iska caabin ah (soo noqnoqda sare, soo noqnoqda hoose), tube alxanka gaaska, tube alxanka foornada

2. sida ku cad tollaynta alxanka - tol toosan oo alxanka tuubo laba jibbaaran, spiral alxanka dhuunta.

Kala soocidda alaabta

Dhuumaha labajibbaaran ee alaab ahaan: tuubo bir laba jibbaaran oo cad, tuubo labajibbaaran oo alloy hoose ah.

1. Birta kaarboonka ee cad waxa loo qaybiyaa: Q195, Q215, Q235, SS400, 20# steel, 45# steel, iwm.

2. Bir daawaynta hoose waxa loo qaybiyaa: Q345, 16Mn, Q390, ST52-3, iwm.

Soocidda heerka wax soo saarka

Tuubbada labajibbaaran sida waafaqsan heerarka wax soo saarka: tuubo labajibbaaran oo heer qaran ah, tuubo labajibbaaran oo halbeeg ah oo Jabbaan ah, tuubo labajibbaaran ee Imperial, tuubo labajibbaaran oo Maraykan ah, tuubo labajibbaaran oo Yurub ah, tuubo laba jibaaran oo aan caadi ahayn.

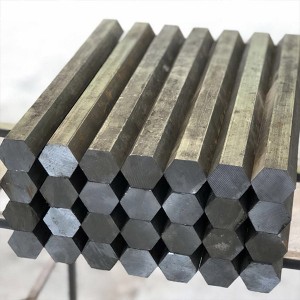

Kala soocidda qaabka qaybta

Tuubbada labajibbaaran iyadoo loo eegayo qaabka kala-soocidda qaybta.

1. Qaybta fudud ee tuubada labajibbaaran: tuubo labajibbaaran, tube afar gees ah.

2. Qaybta isku dhafan ee labajibbaaran: tuubo labajibbaaran oo ubax ah, tuubo labajibbaaran oo furan, tuubbo labajibbaaran oo jiingado ah, tuubo labajibbaaran oo qaabaysan.

Kala soocidda daaweynta dusha sare

Tuubbada labajibbaaran sida waafaqsan daaweynta dusha: tuubo labajibbaaran galvanized kulul, tuubo labajibbaaran oo galvanized electro, tuubo labajibbaaran oo saliid leh, tuubo labajibbaaran oo la picked.

Isticmaal kala saarista

Tuubbada labajibbaaran iyadoo la adeegsanayo: tuubo laba jibbaaran oo qurxin, qalabka mashiinka tuubo laba jibaaran, tuubo laba jibaaran warshadaha mishiinka, tuubo laba jibbaaran oo warshadeed, tuubo laba jibaaran qaab dhismeedka birta, tuubada laba jibaaran ee dhismaha maraakiibta, tuubo laba jibaaran oo baabuur, tuubo laba jibbaaran oo bir ah, tuubo laba jibaaran oo ujeedo gaar ah.

Kala soocidda dhumucda gidaarka

Tuubbada labajibbaaran waxaa lagu kala saaraa dhumucda gidaarka: tuubbo labajibbaaran oo gidaar qaro weyn, tuubo labajibbaaran oo gidaar qaro weyn iyo tuubo labajibbaaran oo gidaar khafiif ah.

| Shaxda qeexida tuubada labajibbaaran ee darbi adag (mm) | Shaxda qeexida tuubada leydi-xagalka ah ee dhumucdeedu tahay (mm) | ||

| 16 ~ 34×0.4 ~ 2.0 | 380~500×380~500×8.0-30.0 | 10~20×20~40×0.6~12.0 | 250~300×100~250×6~30.0 |

| 35×35×1.0~4.0 | Tilmaamaha kale ee dib-u-samaynta waa sida soo socota | 20×50×1.0~2.0 | 400×250×8-30.0 |

| 38×38×1.0 ~ 4.0 | 550×550×10.0-40.0 | 22~40×35~100×0.9~5.0 | 400~×300×8 ~30.0 |

| 40~95×40~95×1.0~8.0 | 600-1000×600-1000×10.0-50.0 | 25×40×0.9~3.75 | 450~500×200~450×8~30.0 |

| 100×100×2.0~8.0 | 50×60×2.0~5.0 | Tilmaamaha kale ee dib-u-samaynta waa sida soo socota | |

| 120~350×120~350×4.0-30.0 | 50~200×60~150×2.0~12.0 | 600~1000×200~800×10~28.0 | |