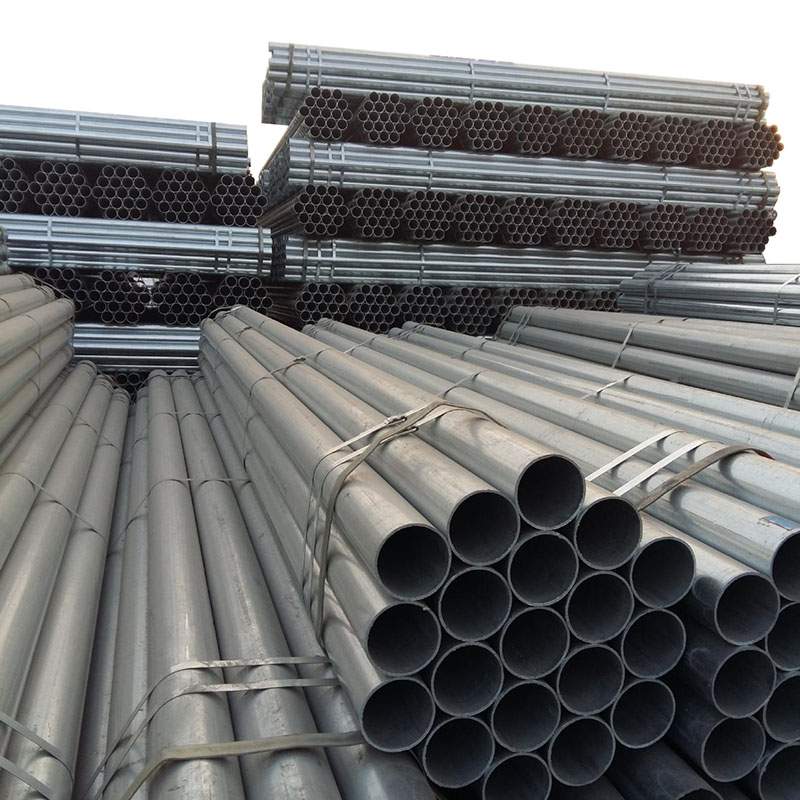

Midabka Duubka Qabow ee Dahaarka leh ee Galvanized Steel Pipe

| Magaca | Bir galvanized | Dhexdhexaad ah | Birta |

| Kala soocidda | Dhuumaha birta galvanized qabow, tuubo galvanized kulul | Baaxadda codsiga | Dhismaha, mishiinada, macdanta dhuxusha, warshadaha kiimikada, korontada, gaadiidka tareenka, warshadaha baabuurta, wadada weyn, buundada, weel, goobaha ciyaaraha, mashiinada beeraha, mashiinada batroolka, mashiinada rajada Ballaari |

| Dhererka | 6m dherer go'an | ||

| Dhumucda derbiga magacaaban (mm) | 2.0, 2.5, 2.8, 3.2, 3.5, 3.8, 4.0, 4.5 |

1.Xoog-jilicsan (σb): Awoodda ugu badan (Fb) ee muunadku ku dhaco xiisad marka la jiido, oo loo qaybiyo cadaadiska (σ) laga helay aagga asalka ah ee isku-tallaabta (So) ee muunada, waxaa loo yaqaannaa xoojinta σb), gudaha N/mm2 (MPa).Waxay ka dhigan tahay awoodda ugu badan ee walxaha birta ah si ay isaga caabiyaan dhaawaca hoos yimaada xiisadda.Halkee: Fb - xoogga ugu badan ee muunadu u adkeyso marka la jiido, N (Newton);Markaa - aagga asalka ah ee isku-tallaabta ah ee muunada, mm2.

2.dhibic dhalid (σs): walxo bir ah oo leh ifafaale wax-soo-saar, walbahaarka marka muunadu ay sii wadi karto inay sii dheeraato iyada oo aan la kordhin xoog (joogto ah) inta lagu jiro habka fidinta, oo loo yaqaan dhibcaha dhalidda.Haddii xooggu hoos u dhaco, dhibcaha dhalidda sare iyo hoose waa in la kala saaro.Halbeegga barta wax-soo-saarku waa N/mm2 (MPa).Dhibicda wax-soo-saarka sare (σsu): walbahaarka ugu badan ka hor inta aan muunadda wax-soo-saarka iyo xoogga marka hore hoos u dhicin;Wax-soo-saarka hoose (σsl): diiqada ugu yar ee marxaladda wax-soo-saarka marka aan la xisaabin saameynta ku-meel-gaarka ah ee bilowga ah.Halkee: Fs - xoogga wax-soo-saarka (joogta ah) ee muunada xiisadda, N (Newton) Markaa - aagga asalka ah ee iskutallaabta ee muunada, mm2.

3.Kordhinta ka dib nasashada: (σ) Imtixaanka xajinta, boqolkiiba korodhka dhererka muunada ka dib marka la jiido miisaankeeda dhererka miisaanka asalka ah waxaa loo yaqaan ' elongation'.Lagu muujiyey σ, cutubku waa %.Halka: L1 - dhererka muunada ka dib marka la jiido muunada, mm;L0 - dhererka shaybaarka asalka asalka ah, mm.

4.Yaraynta jajabka: (ψ) Tijaabada jilbaha, hoos u dhaca ugu badan ee aagga is-dhaafka ah ee hoos u dhaca ka dib marka muunada la jiido iyada oo boqolkiiba qaybta asalka ah ee qaybta isgoysyada loo yaqaan 'jajab jajab'.Lagu muujiyey sida ψ, gudaha %.Halkee: S0 - aagga asalka ah ee iskutallaabta ee muunada, mm2;S1 - meesha ugu yar ee isdhaafka ah ee hoos u dhaca ka dib marka muunada la jiido, mm2.

5.Tusaha Hardness: Awoodda maaddooyinka birta ah ay iskaga caabiyaan galitaanka shay adag oogada sare, loo yaqaan hardness.Iyada oo ku xidhan habka tijaabada iyo baaxadda codsiga, engegnaanta waxaa loo qaybin karaa qallafsanaanta Brinell, Rockwell engegnaanta, Vickers engegnaanta, adkaanta xeebta, microhardness iyo adkaanta heerkulka sare.Tuubada waxaa guud ahaan loo isticmaalaa Brinell, Rockwell, Vickers engegnaanta saddex.

Qallafsanaanta Brinell (HB): Adigoo isticmaalaya kubbad bir ama carbide dhexroor gaar ah, ku cadaadi xoogga tijaabada ee cayiman (F) dusha muunada, ka saar xoogga tijaabada ka dib wakhtiga la cayimay, oo cabbir dhexroorka galitaanka (L) dusha sare ee muunada.Qiimaha qallafsanaanta Brinell waa tirada la helay iyadoo loo qaybinayo xoogga tijaabada aagga dusha wareegsan ee galitaanka.Loogu muujiyey HBS (kubbada birta) ee N/mm2 (MPa).

Tuubbooyinka birta ah ee kulul ee kulul ayaa si weyn loogu isticmaalaa dhismaha, mishiinada, macdanta dhuxusha, warshadaha kiimikada, korontada, baabuurta tareenada, warshadaha baabuurta, jidadka waaweyn, buundooyinka, weelasha, goobaha ciyaaraha, mishiinada beeraha, mishiinada batroolka, mishiinada rajada iyo warshadaha kale ee wax soo saarka. .

Dhuumaha birta galvanized waa tuubo bir ah oo alxan leh oo leh meel kulul ama dusha sare ee elektro galvanized.Galvanization waxay kordhin kartaa caabbinta daxalka ee tuubooyinka birta waxayna sii dheereysaa nolosha adeegga.Dhuumaha birta ah ee galvanized ayaa leh adeegsi kala duwan, marka laga soo tago in loo isticmaalo sida dhuumaha dareeraha cadaadiska hooseeya ee guud sida biyaha, gaaska iyo saliidda, sidoo kale waxaa loo isticmaalaa sida tuubada ceelka saliidda iyo dhuumaha saliidda ee warshadaha batroolka, gaar ahaan Goobaha saliidda badda, sida kuleyliyaha saliidda, qaboojiyaha uumiga iyo nadiifinta dhuxusha iyo beddelka saliidda ee qalabka wax lagu karsado ee kiimikaad, iyo sidii tuubooyin taageero ah oo loogu talagalay tuubooyinka tuubooyinka trestle iyo godad macdanta, iwm.

Dhuumaha biyaha, tuubada saliidda, tuubada qashinka, deyrka waddada, daboolka daadsan, iwm.

| Dhexroorka magacaaban | inch | Dhexroorka dibadda mm | Dhumucda gidaarka mm | Dhumucda gidaarka ugu yar mm | Miisaanka mitirka kg | Miisaanka xididka kg | Miisaanka mitirka kg | Miisaanka xididka kg |

| DN15 Dhuumaha galvanized | 1/2 | 21.3 | 2.8 | 2.45 | 1.28 | 7.68 | 1.357 | 8.14 |

| DN20 Dhuumaha galvanized | 3/4 | 26.9 | 2.8 | 2.45 | 1.66 | 9.96 | 1.76 | 10.56 |

| DN25 Dhuumaha galvanized | 1 | 33.7 | 3.2 | 2.8 | 2.41 | 14.46 | 2.554 | 15.32 |

| DN32 Dhuumaha galvanized | 1.25 | 42.4 | 3.5 | 3.06 | 3.36 | 20.16 | 3.56 | 21.36 |

| DN40 Dhuumaha galvanized | 1.5 | 48.3 | 3.5 | 3.06 | 3.87 | 23.22 | 4.10 | 24.60 |

| DN50 Dhuumaha galvanized | 2 | 60.3 | 3.8 | 3.325 | 5.29 | 31.74 | 5.607 | 33.64 |

| DN65 Dhuumaha galvanized | 2.5 | 76.1 | 4.0 | 3.5 | 7.11 | 42.66 | 7.536 | 45.21 |

| DN80 Dhuumaha galvanized | 3 | 88.9 | 4.0 | ? | 8.38 | 50.28 | 8.88 | 53.28 |

| DN100 Dhuumaha galvanized | 4 | 114.3 | 4.0 | ? | 10.88 | 65.28 | 11.53 | 69.18 |