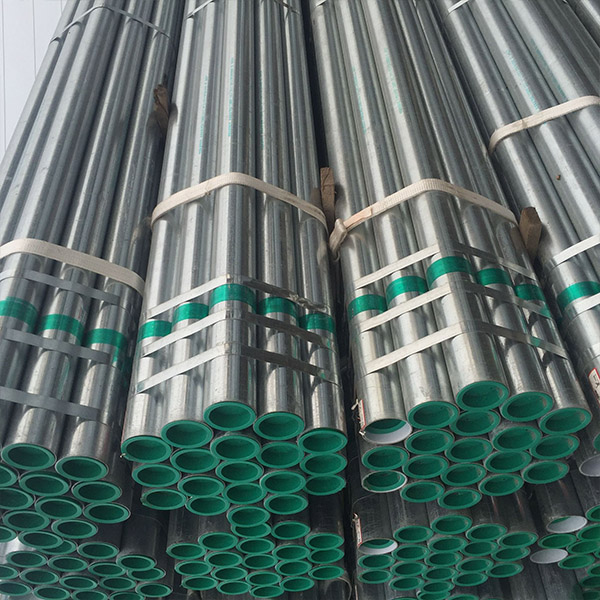

Dhuumaha birta galvanized qabow, Dhuumaha birta galvanized kulul-kulul

1. Pre-galvanized: Dhuumaha birta ee hore loo galvanized waxa si toos ah looga farsameeyaa xariijimaha birta galvanized-kulul.

Lakabka galvanized: 40-60g / sm, haddii loo baahdo lakab galvanized dheeraad ah, waxaa loo farsameyn karaa si waafaqsan. (Dhumucdu waa 0.7mm-4.5mm)

2. Galvanized Hot-Dip: Dhuumaha galvanized Hot-Dip waxay leedahay daahan zinc ka dhumuc weyn marka loo eego dhuumaha horay loo galvanized. Dhuumaha birta madow waxaa la dhex gelin doonaa qubeyska zinc si loo galvanizing. Dahaarka zinc wuxuu noqon karaa: 200-500g / sm

Socodku waa:tuubo madow-alkaline-dhaqidda-biyaha-dhaqidda-qaadashada-biyaha-luqashada-qoynta gargaarka-qallajinta-kulul galvanizing-dibadda afuufaya-qaboojinta-hawo qaboojinta-biyaha qaboojinta -Baasaska-biyaha-luqashada-baaritaanka-keydka-miisaanka.

1. Brand iyo kiimikaad ka kooban

Heerka iyo isku dhafka kiimikaad ee birta ee tuubooyinka birta galvanized waa in ay u hoggaansamaan darajada iyo ka kooban kiimikada birta ee tubooyinka madow sida ku cad GB/T3091.

2. Habka wax-soo-saarka

Habka wax soo saarka ee tuubada madow (alxanka foornada ama alxanka korontada) waxaa doorta soo saaraha. Galvanizing-kulul ayaa loo isticmaalaa galvanization.

3. Isku xidhka dunta iyo tuubooyinka

(A) Tuubooyinka birta galvanized ee la keeno dunta, dunta waa in la makiinado ka dib galvanization. Dufanku waa inuu u hoggaansamaa xeerarka YB 822.

(B) Kala-goysyada tuubooyinka birta waa inay u hoggaansamaan YB 238; Xirmooyinka tuubooyinka birta ee la jeexjeexi karo waa inay u hoggaansamaan YB 230.

4. Guryaha makaanikada Qalabka farsamada ee tuubooyinka birta ka hor inta aan galvanizing waa in ay buuxiyaan shuruudaha GB 3091.

5. Labbiska lakabka galvanized tube birta galvanized waa in lagu tijaabiyaa labbiska lakabka galvanized. Tubada birta ah waa in aanay casaan noqon (midabka naxaasta-dahaadhka ah) ka dib marka lagu dhex geliyo xalalka copper sulfate 5 jeer oo isku xigta.

6. Tijaabada qaloocida qabow Tuubbada galvanized birta leh dhexroor magaceedu aan ka badnayn 50mm waa in la mariyaa tijaabada qaloocida qabow. Xagasha qaloocintu waa 90°, iyo radius foorarsigu waa 8 jeer dhexroorka dibadda. Ma jiro wax buuxin ah inta lagu jiro tijaabada, alxanka muunada waa in la dhigaa dibadda ama qaybta sare ee jihada foorarsiga. Baaritaanka ka dib, waa in aysan jirin dildilaacyo iyo diirinta lakabka zinc ee muunadda.

7. Tijaabada cadaadiska biyaha Tijaabada cadaadiska biyaha waa in lagu sameeyaa clarinet. Ogaanshaha cilladda Eddy hadda sidoo kale waa la isticmaali karaa beddelka tijaabada cadaadiska biyaha. Cadaadiska tijaabada ama cabbirka saamiga isbarbardhigga ee baaritaanka eddy hadda waa inuu buuxiyaa shuruudaha GB 3092. Qalabka farsamada ee birta ayaa ah tilmaame muhiim ah si loo hubiyo isticmaalka ugu dambeeya ee isticmaalka (qalabka farsamada) ee birta.

Shandong Jinbaicheng Metal Material Co., Ltd. waxay ku taal Shandong, saldhigga wax soo saarka tuubooyinka alxanka ee ugu weyn adduunka. Sannado shaqo adag ah ka dib, hannaan horumarineed oo maalgashi oo kala duwan ayaa la sameeyay. Iyadoo la raacayo shuruudaha warshadaynta cusub, waxaan siinaa ciyaar buuxda faa'iidooyinkayaga si aan u gaarno miisaanka, qaab-dhismeedka, iyo tayada. Horumarinta dhamaystiran ee faa'iidooyinka.

Waxaan ku takhasusay iibinta tuubooyinka birta galvanized, tuubooyinka birta kulul duuban, tuubooyinka aan kala go 'lahayn,. Dhowr sano oo horumar ah ka dib, waxaan dejinay muddo dheer

La shaqee macaamiisha in ka badan 70 waddan oo adduunka ah, oo ay ku jiraan Kanada, Australia, Singapore, Thailand, South Korea, Vietnam, Mexico, Chile, Peru, iyo New Zealand. Wax-soo-saarka sannadlaha ahi waa 700,000 oo tan.

Habka isku xirka birta galvanized: dunta, alxanka.

Isku xirka jeexdin duub

(1) Dildilaaca alxanka duudduuban

1. Si khafiif ah feeraha alxanka ee gidaarka gudaha ee jeexdin cadaadiska qayb ka mid ah biibiile si loo yareeyo iska caabinta jeexdin duuban.

2, Hagaajin dhidibka birta birta iyo qalabka rogrogmada, una baahan tuubada birta ah iyo qalabka rogrogmada si ay u noqdaan kuwo siman.

3. Hagaajin xawaaraha riixaya ee jeexdin, iyo jeexdin wakhtiga samaynta ma dhaafi karo sharciga, codso xoog siman oo tartiib ah.

(2) Jeex-jeex jeexjeexa birta birta jaban

1. Si khafiif ah feeraha alxanka gidaarka gudaha ee jeexdin cadaadiska qaybta afka biibiile si loo yareeyo iska caabinta jeexdin rogmada.

2, Hagaajin dhidibka birta birta ah iyo qalabka rogrogmi kara, oo u baahan tuubada birta iyo qalabka rogrogmada si ay u noqdaan kuwo siman.

3. Hagaajin xawaaraha riixitaanka, xawaaraha cadaadisku kama dhaafi karo sharciga, xoog u mari si siman oo tartiib ah.

4. Hubi ballaca iyo moodka rullaluistuyada taageerada iyo rullaluistemadka cadaadiska qalabka jeexdin rogrogmi kara, oo hubi haddii ay jirto isku-dheelli-tirnaan la'aanta cabbirka labada rollers, taas oo keeni karta suuxdin.

5. Isticmaal caliper vernier si aad u hubiso in jeexdin tuubada birta la cayimay iyo in kale.

(3) Godka ay samaysay mishiinka jeexdintu waa inuu buuxiyaa shuruudaha soo socda

1, Dusha sare ee dhamaadka tuubada ilaa qaybta jeexdintu waa inay ahaataa mid siman oo aan sinnaan lahayn iyo calaamadaha duubista.

2, Xarunta jeexdintu waa inay ahaataa mid ku kooban gidaarka tuubada, ballaca iyo qoto dheer ee jeexdintu waa inay buuxiyaan shuruudaha, oo hubi in nooca qaybta xajintu sax tahay.

3. Saliid mari giraanta caagga ah oo hubi in giraanta xidhidhiyaha caagtu ay dhaawacday. Saliiduhu waa in aanu noqon saliid saliid.

Isku xirka alxanka

1. Dhuunta afka birta galvanized ma aha mid toosan oo waxaa jira dhib ah in afka qallafsan ee tuubada birta ka dib. Waxaa lagu talinayaa in la gooyo madaxa tuubada muddo gaaban ka hor inta aan la farsameyn.

2, Ka dib markii tuubooyinka birta ee birta ah ee galvanized ay ku xiran yihiin, labada nozzles si adag looma xirin, taasoo keentay dhumuc aan sinnayn oo ah isku-dhafka welded; iyo dhuumaha waa elliptical sababo iyada u gaar ah ama kuuskuusan gaadiidka. Waxaa lagu talinayaa in la gooyo madaxa tuubada muddo gaaban. Mar kale habsoco.

3. Ka bacdi naas-nuujinta tuubooyinka birta galvanized-ka ah la dabadaa, nabarro ayaa ka soo baxa naas-nuujinta:

4. Sababo farsamo inta lagu jiro alxanka awgeed.

5. Waxaa jira nodules zinc ah oo ku jira tuubada, taas oo keeni karta dhibaato alxanka iyo finan. Haddii qanjidhada zinc ay aad u weyn yihiin oo ay aad u badan yihiin, tuubooyinka zinc ee fudud waa in meesha laga saaraa.

Isku xirka fiilada

1, Xarkaha dunta leh: Dhuumaha xadhigga leh iyo xadhigga dunta leh lama xidhiidhi karo si buuxda, debciya, gooya qaybta xidhidhka random, oo dib u rakib dunta.

2. Duubka birta ah iyo dunta xuubka tuubada isma dhigmaan lamana xidhiidhin karo. Dhuumaha tuubada waa in la bedelaa ama qalabku waa in la hagaajiyaa oo dib loo dhejiyaa.

3. Daabacaadda maqan ka dib marka tuubada birta la dunto: Cabbir in dhumucda gidaarka tuubada birta ay buuxin karto shuruudaha dhumucda caadiga ah ee tuubada dunta leh

| Nooca | EN10210 Dhuumaha birta galvanized |

| Darajo | S235jrh (1.0039), s275j0h (1.0149), s275j2h (1.0138), s355j0h (1.0547), s355j2h (1.0576), s355k2h(1.0512), . 5.9 (1.0512), 7 (9), 7 (9), 5.9 (1.0512), s27 (1.0512), s27 (1.0149), s275j2h (1.0138), s355j0h (1.0547) s s420nh (1.8750), s420nlh (1.8751), s460nh (1.8953), s460nlh (1.8956), s235jrh(1.0039), s275j(1.8750), s1(1.8953), s420.8 s460nh (1.8953), s235jrh (1.0039), s275j5 (j5h), 5j5(04j), 5h (1.8751), 5h (1.8751), s460nh (1.8953) 1.055 (j5h), 5s31. s355j2h (1.0552) (1.0493), s275nlh (1.0497), s355nh (1.0539), s355nlh (1.0549), s420nh (1.8750), s420nlh (1.8750), s420nlh (1.3h.1), 6.5h. s460nlh (1.8956) , s275mh (1.8453) (m843) s275ml (s355mlh(1.8846)s420mh (1.8847)s420mlh(1.8848)s460mh |

| Dhumucda | 3mm - 30mm |

| Shahaado | Ul api |

| Adeegga habaynta | Laacidda, alxanka, furfurida, feerka, goynta |

| Magaca alaabta | Dhuumaha birta ah ee aan cillad lahayn |

| Qaabka | Wareegga wareega. leydi |

| Dhererka | 3-12m |

| Moq | 1 tan |

| Farsamada | Kulayl kulul oo qabow duuban |