Birta aan Daxalka lahayn ee Sare ee Nickel Alloy 1.4876 Daxalka Iska caabinta Daxalka

1.4876 waa Fe Ni Cr oo ku salaysan xal adag oo la xoojiyay daxalka u adkaysta heerkulka sare. Waxaa loo isticmaalaa in ka hooseeya 1000 ℃. 1.4876 daxalka u adkaysta waxay leedahay iska caabin heerkul sare oo heer sare ah iyo qaab dhismeedka wanaagsan, xasiloonida microstructure wanaagsan, farsamaynta wanaagsan iyo waxqabadka alxanka. Way fududahay in la sameeyo hab qabow iyo kulul. Waxay ku habboon tahay samaynta qaybo u baahan heerkul sare iyo shaqo waqti dheer ah oo ku hoos jira xaalado dhexdhexaad ah oo adag.

1.4876 daxalka u adkaysta waxay leedahay iska caabin dildilaaca daxalka wanaagsan, stress iska caabin dildilaaca in chloride biyaha, iska caabinta daxalka ee uumiga, hawada iyo isku darka carbon dioxide, iyo caabbinta daxalka wanaagsan ee acids organic sida HNO3, HCOOH, CH3COOH iyo propionic acid.

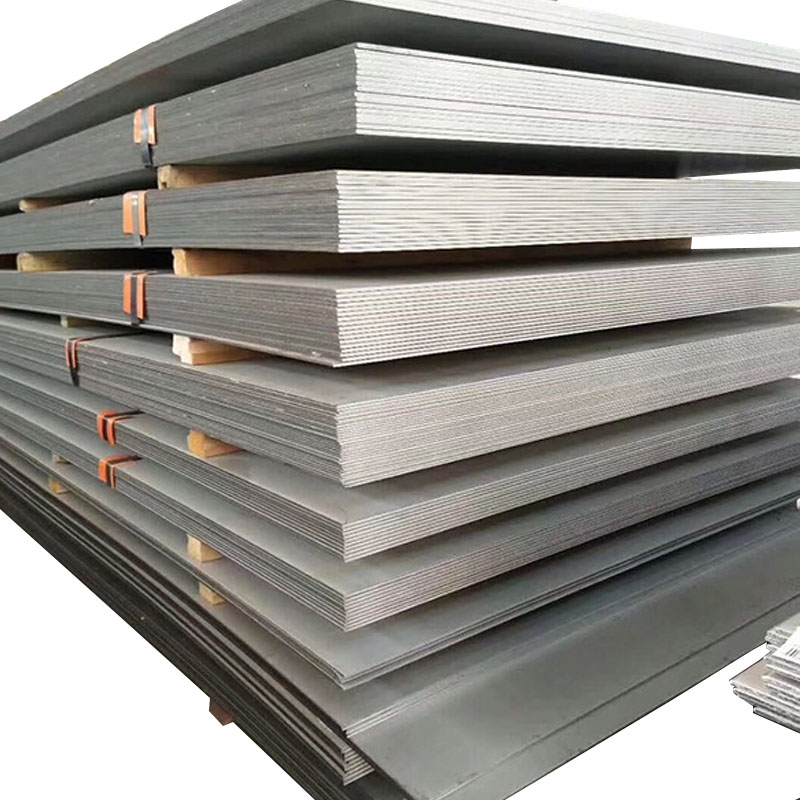

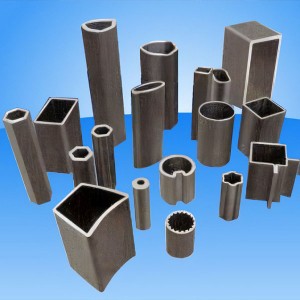

1.4876 Heerarka fulinta Alloy-ka daxalka u adkaysta waxaa jira heerar taxane ah oo wadamo kala duwan ah. Heerarka ajnabiga ah guud ahaan waa UNS, ASTM, AISI iyo din, halka heerarka qarankeena ay ka mid yihiin heerka GB / t15007, ul heerka GB / t15008, heerka saxan GB / t15009, heerka tuubada GB / t15011 iyo suunka GB / t15012.

Heerka Jarmalka:1.4876, x10nicralti32-20, American Standard no8800, 1.4876, heerka qaran gh1180, ns111, 0cr20ni32fe

Kaarboon C: ≤ 0.10, Silicon Si: ≤ 1.0, manganese Mn: ≤ 1.50, chromium Cr: 19 ~ 23, nikkel Ni: 30.0 ~ 35.0, aluminium al: ≤ 0.15 ~ 0.6, copper ~ 0.5, titanium Ti. : ≤ 0.75, fosfooraska P: ≤ 0.030, baaruud s: ≤ 0.015, iron Fe: 0.15 ~ dheeraad ah.

1.4876 daxalka u adkaysta daxalka ayaa leh waxqabad shaqo oo kulul oo wanaagsan. Heerkulka shaqada kulul waa 900 ~ 1200 iyo foorarsiga kulul ee samaynta waa 1000 ~ 1150 darajo. Si loo yareeyo u janjeera daxalka intergranular ee alloy, waa in ay dhex maraan 540 ~ 760 digrii aagga dareenka sida ugu dhakhsaha badan. Jilcinta dhexdhexaadka ah ayaa loo baahan yahay inta lagu jiro shaqada qabow. Heerkulka daawaynta kulaylku waa 920 ~ 980. Heerkulka xalka adag waa 1150 ~ 1205. Xaaladda alxanka ayaa wanaagsan, iyo habka alxanka caadiga ah.

Cufnaanta: 8.0g/cm3, barta dhalaalka: 1350 ~ 1400 ℃, awoodda kulaylka gaarka ah: 500J / kg. K, iska caabin: 0.93, modules laastikada: 200MPa.

1.4876 daxalka u adkaysta daxalka ayaa leh iska caabin aad u wanaagsan oo iska caabin daxalka ah ee biyaha ka kooban chloride iyo diirada hoose ee NaOH. Waxaa si weyn loo isticmaalaa in lagu soo saaro qalabka daxalka u adkaysta stress halkii 18-8 austenitic steel. Waxaa loo istcimaalay uumi-dhaliyaha biyaha cadaadiska, gaaska heerkul sarreeya ee qaboojiyaha, sodium qaboojiyaha kulaylka degdega ah iyo tuubada uumiga kulul ee warshadaha tamarta. Waxaa loo isticmaalaa qaboojiyaha HNO3, tuubada dildilaaca anhydride acetic iyo qalabka kala duwan ee kulaylka ee warshadaha kiimikada.