Bimetal Composite Wear-U adkaysta Saxanka

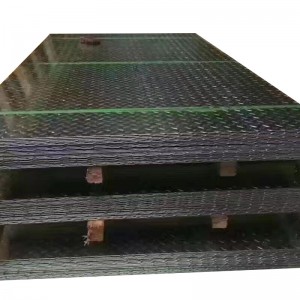

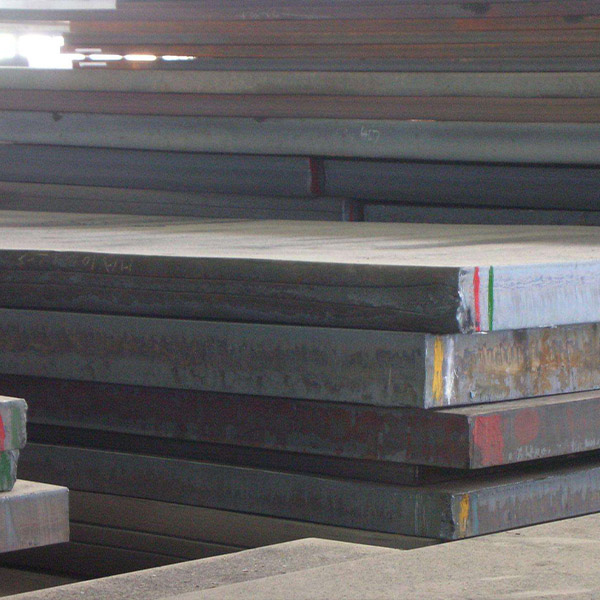

Waxa jira xidhiidh bir ah oo u dhexeeya lakabka xidhashada u adkaysta ee daawaha birta u adkaysta iyo substrate-ka. Iyada oo loo marayo qalab gaar ah iyo habka alxanka tooska ah, xargaha alxanka alxanka ee adag ee sarreeya ayaa si isku mid ah loogu dhejiyaa alaabta saldhigga ah. Tirada lakabyada isku dhafan waa hal ilaa laba ama xitaa dhowr lakab. Inta lagu jiro habka isku dhafan, sababtoo ah saamiga kala duwan ee hoos u dhaca ee daawaha, dildilaacyo isku dhafan ayaa soo baxaya, taas oo ah muuqaal muhiim ah oo ka mid ah saxannada birta ah ee xiran.

Saxanka birta ah ee u adkaysta waxay leedahay caabbinta xidhashada sare iyo waxqabadka saamaynta wanaagsan. Waa la gooyn karaa, foorarsan kartaa, alxanka, iwm., waxaana lagu xiri karaa qaabab kale iyadoo la isticmaalayo alxanka, alxanka, isku xirka boodhka, iwm. sibidh, koronto, dhalada, macdanta, qalabka dhismaha, leben iyo tiles iyo warshado kale. Marka la barbardhigo agabka kale, waxay leedahay wax qabad qiimo sare leh waxaana doorbiday warshado iyo soosaarayaal aad u badan. .

Marka loo eego habka qallafsanaanta iyo alxanka, noocyada ugu muhiimsan ee taarikada u adkaysta waa: NM360, NM400, NM450, NM500.

1) Warshad tamarta kulaylka ah: Dhererka dhagxaanta dhuxusha dhuxusha dhexdhexaadka ah, godka marawaxadaha, boodhka tuubada daloolka, tuubada dambaska, xadhkaha marawaxadaha baaldi, tuubada isku xidha, mishiinka dhuxusha, dhuxul dhuxusha iyo burburiyaha mishiinka, gubanaya gubanaya, dhuxusha oo dhacay xuubka hoopper iyo funnel, foornada ilaalinta kulayliyaha hawada ka hor, weelka hagaha kala soocida. Qaybaha kor ku xusan ma laha shuruudo sare oo ku saabsan adkaanta iyo xirashada caabbinta saxan birta u adkaysta, iyo saxanka birta u adkaysta ee dhumucdiisuna tahay 6-10mm ee walxaha NM360/400 waa la isticmaali karaa.

2) Dayrka dhuxusha: weelka quudinta iyo dahaarka hopper, baadiyaha hopper, marawaxada, saxan hoose riixo, boodhka ururiyaha duufaanka, liner hagaha kookaha, dahaarka kubbada dahaarka, stabilizer, gambaleel feeder quudiyaha iyo kursiga salka, baaldi dahaarka cajiinka, giraanta quudiyaha, saxanka hoose ee xamuulka qaada. Deegaanka shaqada ee dayrka dhuxusha waa mid adag, waxaana jira shuruudo gaar ah oo loogu talagalay iska caabinta daxalka iyo xirashada caabbinta saxanka birta ah ee u adkaysta. Waxaa lagu talinayaa in la isticmaalo saxanka birta u adkaysta ee NM400/450 HARDOX400 oo dhumucdiisu tahay 8-26mm.

3) Warshad sibidhka: dahaarka dahaarka, baadiyaha dhamaadka, boodhka ururiyaha duufaanka, daabka kala qaybiya budada iyo dahaarka hagaha, marawaxada iyo dahaarka, dahaarka baaldi dib u warshadaynta, maroojii conveyor saxan hoose, qaybaha tuubooyinka, frit qaboojinta saxan dahaarka, gudbinta looxa dahaarka. Qaybahani waxa kale oo ay u baahan yihiin taargooyin bir ah oo xidhan oo leh adkaysi fiican iyo iska caabin daxalka, iyo taarikada birta xidhan ee dhumucdeedu tahay 8-30mmd ee ka samaysan NM360/400 HARDOX400 waa la isticmaali karaa.

4) Mashiinada rarida: dejinta saxan saxan shiidan, xabagta xabagta, saxan daab qabasho, looxa qashin qubka ee otomaatiga ah, jidhka xamuulka qaada. Tani waxay u baahan tahay taargooyin bir ah oo u adkaysta xidhashada oo leh xoog aad u sarreeya oo u adkaysta xidhashada. Waxaa lagu talinayaa in la isticmaalo taarikada birta ah ee u adkaysata ee leh walxo NM500 HARDOX450/500 ah iyo dhumucdiisu tahay 25-45MM.

5) Mashiinada macdanta: dahaarka, dahaarka, dahaarka qaada iyo baffles ee alaabta macdanta iyo burburinta dhagaxyada. Qaybaha noocan oo kale ah waxay u baahan yihiin iska caabin aad u sarreeya, iyo walxaha la heli karo waa NM450/500 HARDOX450/500 taarikada birta u adkaysta oo dhumucdiisu tahay 10-30mm.

6) Mashiinada dhismaha: saxanka iligga riixaya sibidhka, munaaradda isku dhafka shubka ah, saxanka dahaarka qasaha, saxanka dahaarka boodhka ururiyaha, saxanka caaryada mashiinka lebenka. Waxaa lagu talinayaa in la isticmaalo taarikada birta u adkaysata ee ka samaysan NM360/400 oo dhumucdiisu tahay 10-30mm.

7) Mashiinada dhismaha: xamuulka, cagaf-cagafleyda, taarikada baaldiga qodista, taarikada dhinaca, taarikada hoose ee baaldiga, daabadaha, qalabka qodista rotary-ga. Mashiinada noocan ahi waxay u baahan yihiin taargooyin bir ah oo xoog badan oo xidhan oo leh tamar aad u sarreeya Qalabka la heli karo waa NM500 HARDOX500/550/600 taarikada birta u adkaysta ee xoogga badan oo dhumucdeedu tahay 20-60mm.

8) Mashiinnada birta: mishiinka birta birta, suxulka gudbinta, birta birta birta, xadhkaha xoqida. Sababtoo ah mashiinada noocaan ah waxay u baahan yihiin heerkul sare oo adkaysi u leh iyo taarikada birta ah ee aad u adkeysata. Sidaa darteed, waxaa lagu talinayaa in la isticmaalo HARDOX600HARDOXHiTuf taxane ah oo xirashada taarikada birta ah.

9).